When we last left off, our hero had just finished building 2 home office cabinets. Will she succeed? Will she drill more pocket holes? Keep reading to find out what happens next…

How to Build a Mini Home Office Cabinet

After some thinking about my design, I settled on building a mini cabinet as a connector piece.

By now I was feeling like a pro at constructing cabinets. This smaller cabinet was essentially the same as the two I previously built, except on a smaller, more squarish scale. I wanted it to be recessed, so I kept that in mind when figuring out my measurements.

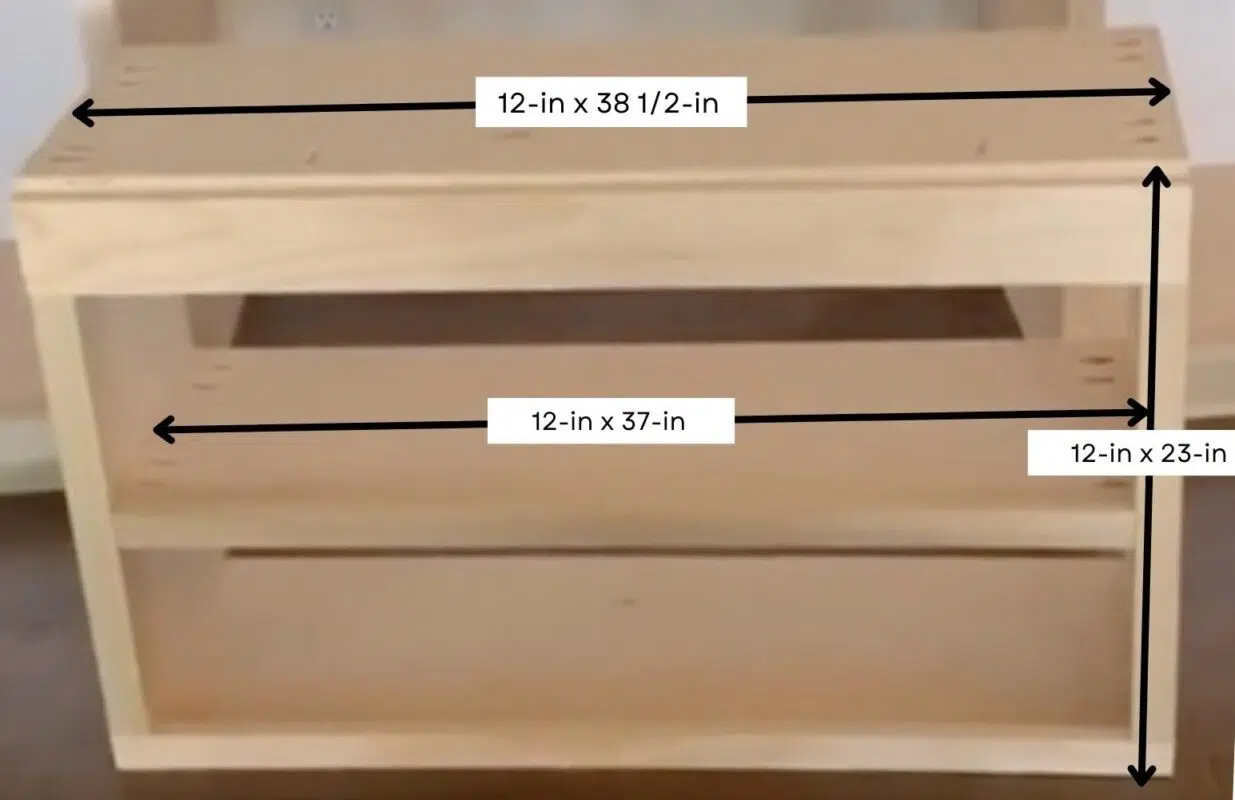

I placed my cabinets against the wall in their permanent spot, measured the distance between each, and cut my wood for the box. My 2 vertical walls measured 12 inches by 23 inches. The top and bottom shelf measured 12 inches x 38 1/2 inches. The middle shelf measured 12 inches x 37 inches.

Back at it again with the pockets holes, I drilled 2 sets into the walls of my box. My clamps helped keep everything tight and square as I drilled my box together. I made sure the pocket holes were facing out when attaching the boards together since those sides wouldn’t be seen.

To attach the middle shelf, I added 2 sets of pocket holes to the ends, and screwed it into the cabinet. The pocket holes on the shelf were facing up since it will be high enough for them not to be seen.

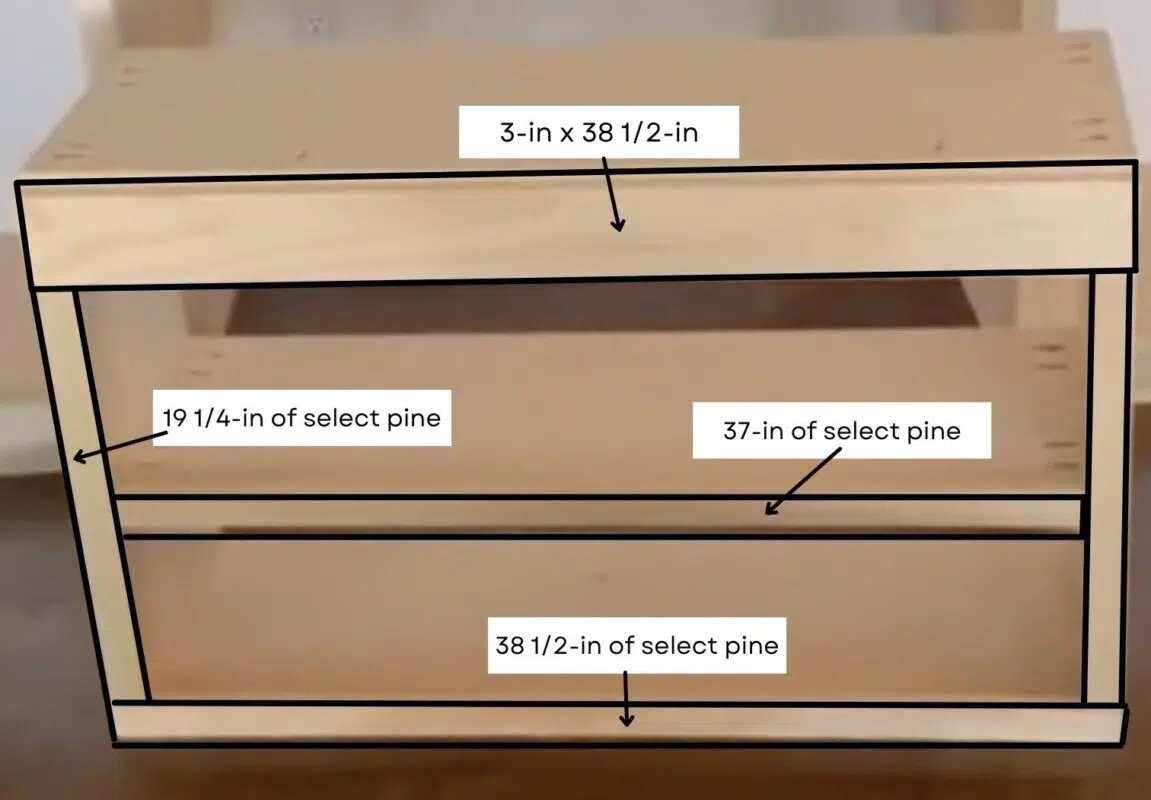

I made a frame similar to that of the larger cabinet.

The top piece measured 3 inches by 38 1/2 inches. I used select pine to cut 2 pieces measuring 19 1/4 inches, 1 piece measuring 38 1/2 inches, and 1 piece measuring 37 inches.

Making sure everything was flush and square, I screwed my frame together through pocket holes, used brand nails to attach the frame to the cabinet, added bead board to the back.

How to Secure the Mini Cabinet to the Wall

I used a stud finder to locate and mark the studs in my wall. The back top of the 3 cabinets were marked to match up with a corresponding stud, and an L bracket was attached to the cabinet at that mark. I attached 2 L brackets to each cabinet, and through the brackets, I attached each cabinet to the wall directly into the corresponding stud.

How to Trim, Caulk, and Prime the Office Cabinets

The finish line is in sight folks. Next up: CROWN MOLDING!! Everyone’s favorite! (said no one ever)

Crown molding can be a beast but it comes together with some math and a miter saw. I don’t feel qualified to give a crown molding tutorial because… well… let’s just say it’s not my strong-suit. But I tell you what I can caulk like it’s nobody’s business. If you need some help with crown molding like I did, there are approximately a million excellent tutorials on YouTube like this one. The baseboards were a breeze. I nailed both to my wall with my nail gun, and it was ready for some caulk.

The trick with caulking is using a good caulk gun, baby wipes, and an index finger you won’t be needing for a couple days afterwards. Caulk every joint and corner. If you don’t know if it’s something you should caulk, just caulk it. Don’t forget your crown and baseboards.

After your caulk is dry, tape everything off and give your cabinets a good priming. I used a foam roller and water based kilz primer.

How to Add Additional Shelving

I cut plywood into 19 1/4 inch x 30 1/4 inch boards that fit inside my cabinets behind the lip of the frame. These shelves didn’t need to be secured to the cabinet because earlier I drilled adjustable shelving holes. That’s right folks, I’ve come full circle. I made sure to measure well because if the shelf’s width was a tad short, it wouldn’t sit on the pegs.

Look at all those raw edges. Blah. I wanted my shelves smooth and paintable, so I used more of my edge banding on the front of each new shelf.

The new shelves needed priming. I concocted this nifty device to hang my shelves from so I could use my Graco Paint Sprayer. All you need are plastic hangers, cup hook screws, and scaffolding. If you’re a normal person and don’t have scaffolding, just prime each side of the shelf with a foam roller. Or improvise with a couple of ladders like I did for the rest of the doors.

How to Paint the Office Built In

I chose the paint color Gossamer Veil by Sherwin Williams. I settled on using my Graco paint sprayer to apply my paint. This method takes a lot of prep work but the finish I get is soooo worth the extra time. If you don’t have a sprayer, bust out the trusty foam roller.

The additional shelving I had primed earlier was painted outside of the cabinet.

I used my zip wall to protect the rest of my house from the paint dust. Every seam, hole, and crack was taped shut because I’m not messing around.

She’s a beauty. And the cabinets look nice too…. C’mon guys I’m joking. My Graco Paint Sprayer required no thinning and it gave the cabinets such a nice finish. Well worth the prep work.

Check out Part 3 of HOW TO Build Office Cabinets to see how to build the desk, tile the backsplash, and add the cabinet doors.

Check out Part 1 of HOW TO Build Office Cabinets to see how to build the boxes and attach the framing.

Feel free to leave a comment if you liked this post or have any questions.

All of my videos for this project can be found in my Office Part 1 and Office Part 2 highlights on my instagram account @crystelmontenegrohome.