Do you hate useless half-shelves in kitchen cabinets as much as I do? When we remodeled our kitchen, I purchased some basic stock cabinets from Home Depot with them inside, and they are SO hard to reach and grab items off of, not to mention not very functional. They needed to go! So, I decided to add pull-out shelving instead. Adding custom pull-out shelves has become one of my favorite things to do to add functionality to any space, and it’s a total game-changer! I am going to show you just how easy they are to build.

This post includes affiliate links.

Tools

Brad Nailer

Drill

Miter Saw

Table Saw

Circular Saw

Router

½” Router bit

Tape Measure

T-Square Ruler

Laser Level

Mini Level

Supplies

Wood Glue

Brad Nails

Drawer Slides & Screws

Materials

1×2 Select Pine Boards

½” Plywood

2x4s for Bump Outs

Preparing the Cabinets for the Drawer Slides

The door hinges stick out a bit, and I wanted the custom pull-out shelves to clear them when sliding in and out, so I needed to do some measurements around those first.

I started by measuring the distance between the fattest part of the hinges on both sides of the cabinet; my measurement came out to 31 ¼”. That’s how wide I needed my shelf to be.

Then, I had to find out what the distance was between the side of the cabinet and the front of the hinge on each side of the cabinet because I had to put something in there that was going to fill in the gap so that my drawer slide could be mounted and clear the hinge when sliding in and out. Unless I added a piece of wood to bump out my drawer slides, my pull-out shelving would hit the frame each time.

I used a laser level to line up exactly where I needed my top drawer to go. It’s important that both drawer slides are exactly level when you install them; otherwise, they won’t slide out properly. Then, I took a 2×4 piece of wood cut to the depth of my cabinet and used wood glue and multiple screws to mount it to the side of the cabinet. When mounting it, I ensured the wood piece was directly under my laser-level line. Then, I repeated the same steps on the other side of the cabinet.

Installing Drawer Slides for the Pull-Out Shelving

Next, I installed the drawer slides for the top drawer in the cabinet. To install them, I took one slide and lined the top end up with the top of the bump-out board and the laser level line. I then extended the slide entirely out and drilled the screws into the slots within the slide.

Once all screws were in, I pushed the slide back into place and mounted the other slide to the other side of the cabinet. Once both slides were mounted, I measured them to ensure they were level and in the correct spots. Then, I continued these steps to install the drawer slides for the bottom drawer.

Measuring and Cutting the Frame of the Custom Pull-Out Shelves

If you followed along with how I built my trash bin cabinet drawer, I essentially did the same thing for the kitchen cabinet drawers, but I replaced the top half shelf and the bottom shelf with custom pull-out shelves instead. These shelves were a little different to build but much easier.

The shelves for this cabinet needed to be much shorter, wider, and stronger because the cabinet is much wider than the trash bin cabinet is. Therefore, the bottom of each shelf needed more strength than just the screws, brad nails, and glue that was used for the trash bin cabinet could offer.

To build the bottom and top drawers, I used 1×2 select pine for the frame of each drawer. It’s also the same stuff I used for my face frames on all the cabinets I built. I decided to get a little fancy by adding a wooden border around my plywood shelf, but it’s totally unnecessary! You could just take a piece of 3/4″ plywood cut to dimensions, add some iron-on edge banding to make the edges pretty, and then screw the drawer slides into that! But if you want to add the pretty border, read on.

The amount of space in between my two drawer slides was 30 ½”, so I went ahead and cut two of the frame pieces to 30 ½” and then subtracted the width of each wood frame piece multiplied by 2 to find my sides.

I took a piece of the frame edging and measured 30 ½”, then cut it to size with my miter saw and repeated for the second piece. Those two pieces were used for the front and back of the drawer. I wanted the total depth of my drawer to be 22 ½”. So, I took 22 ½” and subtracted the total thickness of both frame pieces, which was 1 ½”, and that left me with 21”. Then, 21” was the length I needed to cut both side edges to for my drawer.

To get a better visual, the front and back pieces of the frame were cut down to 30 ½”, and the two side edges were cut to 21”. I repeated this for my second drawer. Then, I started routing the edge pieces for my plywood to fit in.

Using the Router to Carve the Drawer Frame Edges

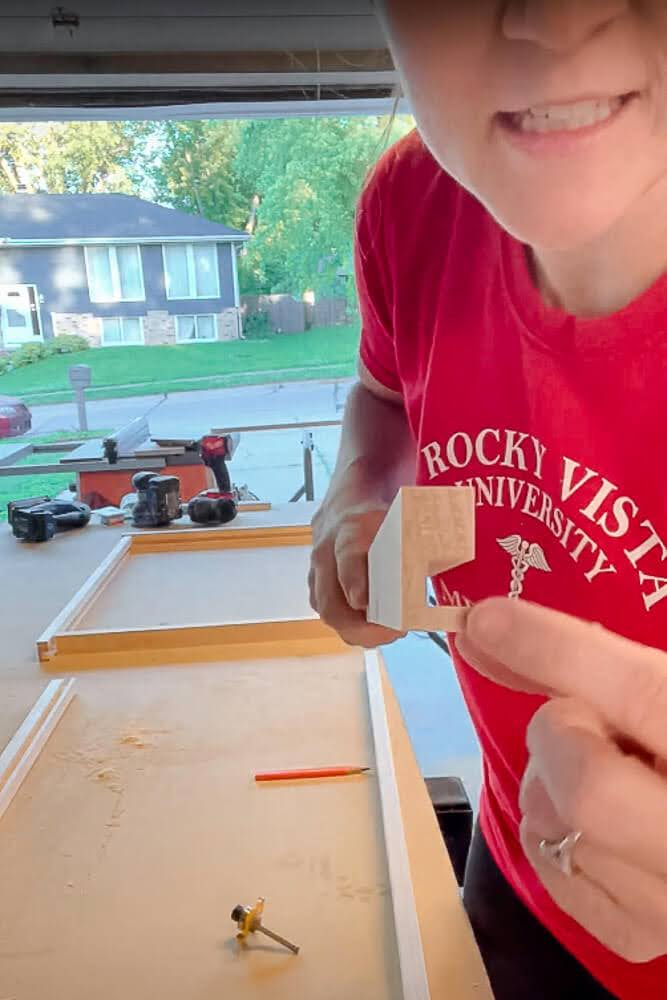

When building the drawer frames, I got a little bit fancy and used my 1/2″ router bit on my router because it’s the same thickness as the plywood I used for each drawer’s bottoms. The router bit was used to carve out a slot in each frame piece so that my plywood could sit into my frame. That gave the edges of my plywood something to sit on, making the whole drawer sturdier.

I first ran a test piece through my router and the plywood piece fit in the slot beautifully. Then, I ran all of the edge pieces through the router to create the slot for the plywood to sit in. After each piece was routed out, the most challenging part was over.

When using the router to cut through each edge, I made sure one side of each frame edge was ½”.

Measuring and Cutting the Plywood to Size

After all frame edges were routed, I put them together to make a square. Then, I measured the inside diameter of the square and added 1”, so ½” on each side of the square edges, and that’s how big I cut each piece of plywood for the bottoms of the drawers.

So, the distance between the front inside edges of the drawer was 28 ¾”, but cut to 29 ¾” to make up for the spacing inside the router slots. Then, I measured the inside edge of the sides of the drawer, which was 21”, so that side of the plywood needed to be cut to 22”. Again, the extra inch makes up for the space within the routed-out slot in each edge piece. So, 29 ¾” x 22” was the dimensions of each drawer’s bottom.

I broke out my T-Square ruler and circular saw and started cutting the plywood to size. After measuring and marking where the first line should be cut, I clamped a straight edge board on the line, then used my circular saw to cut straight up against the clamped board, ensuring the cut was going to be straight. Then, I trimmed the edges down to the exact size using my table saw.

After the plywood used for the custom pull-out shelves was cut to size, I wanted to see how they fit within the routed-out frame pieces; they fit perfectly! So, I put wood glue in each of the troughs within each edge piece and then brad nailed the edges onto the sides of the plywood.

Attaching the DIY Cabinet Pull-Out Shelves to the Drawer Slides

Once the drawers were put together, I brought them inside and had to attach them to the drawer slides. To attach them, I cut four 2×4 supports long enough to help support the drawers while I used my laser level to ensure they were sitting evenly.

Then, I measured and marked where I wanted the front of the drawer slide to be attached to both sides of the drawer.

Once that was figured out, I extended the drawer slides all the way out, pressed down on the inside tab, and separated them so that one half was still mounted to the inside of the cabinet and the other half was completely off. The side that was completely off was then screwed into markings I made on the side of the drawer.

After the slides were mounted to the drawer, I put the drawer in place and attached the slides back together until they were latched and the drawer pulled in and out smoothly. I repeated these steps for the bottom drawer.

Now, I have two functioning custom pull-out shelves that add a lot more real estate to the inside of my cabinets! What do you think? Would you do this to any of your cabinets? Let me know in the comments!

I just love love love what you did I also bought cabinets that are deep and can’t get anything out .So I also am placing sliding shelves. I had someone make drawers and will place my plates and bols into .love what you have done

I’m thrilled I could give you some inspiration!

How did you remove the original half shelf? (The pointless one)

My half shelf was sitting on a peg and I could lift it out pretty easily. If yours is permanent, use a multitool to take it out. Just go slow and you should be fine.

How do you get the old half shelf out?? I have a narrow cabinet that I want to use for pan storage but it has a half shelf. I want to just cut into it and hopefully pull it out but my husband is concerned it will damage the cabinet box.

My cabinets had adjustable shelving, so that half shelf was sitting on a peg and I could lift it out pretty easily. But, if you have to remove yours, use a multitool. As long as you’re careful, it won’t damage the structure of your cabinet box.